The Design process

The process from the initial design, prototype, fit prototype, spec sheets, endless fittings, corrections, final sales samples, photoshoot and catalogue – is crazy long.

The second stage is the pre-sell to our gorgeous stockists. Pre orders are officially known as “indents” and allow retailers to order exactly what they need in the colours and sizes for their customers.

This enables us all to produce mindfully by placing exact quantities and not over order.

The final stages are production, shipping and warehousing when the stock finally arrives and is stacked onto the shelves waiting to be sent out for the new season ahead.

Sourcing

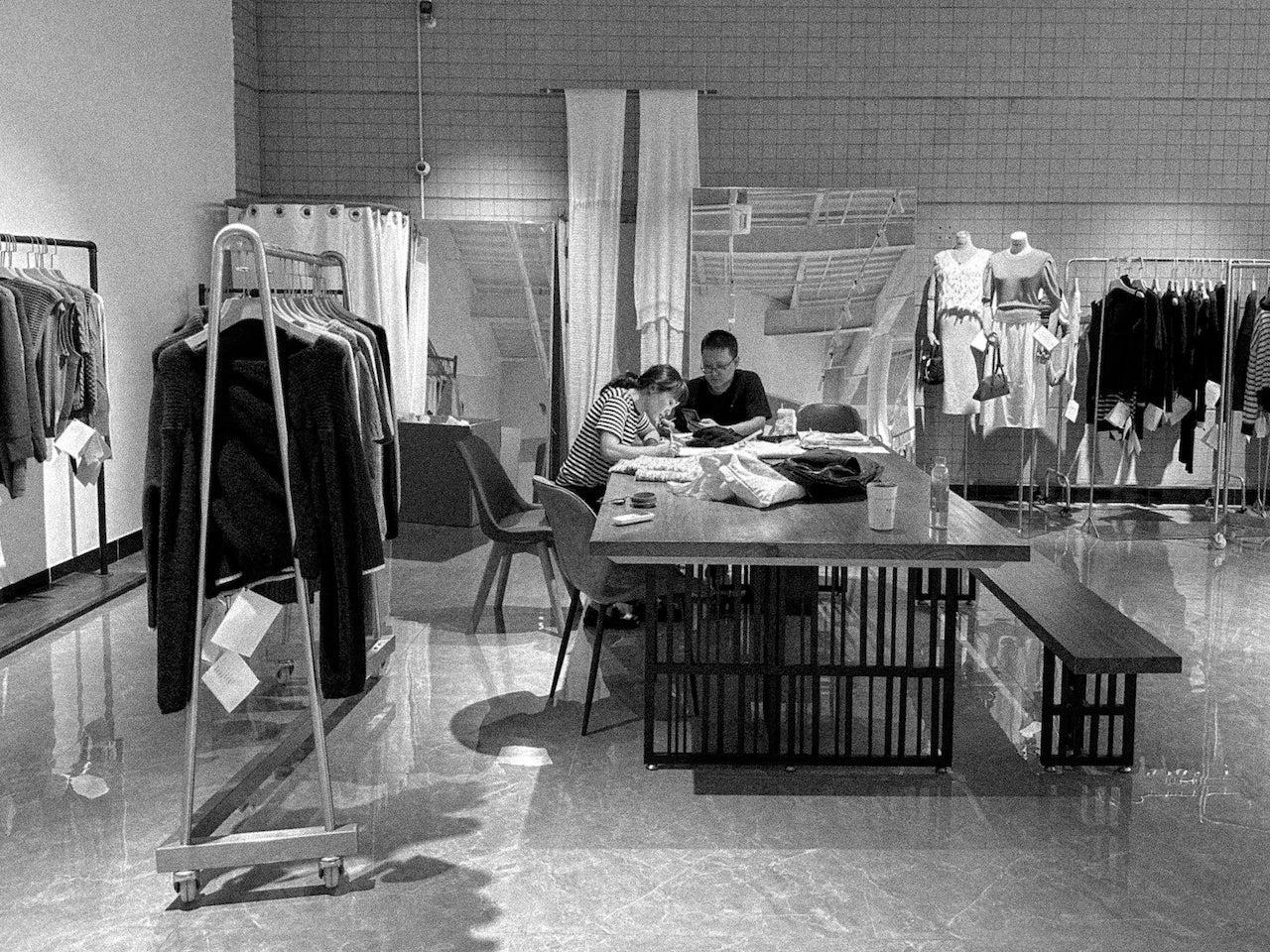

Before we start designing pieces, we source fabrics and trims from various locations. We source directly from the markets in China ourselves and in between our wonderful assistants on the ground in China or India will assist us.

Sourcing is a real highlight when you find exactly what you are looking for! However, don’t be fooled, there’s lots of hot sweaty hours on foot (kilometres!) to find the exact fabric, trim or accessory required for the next season.

Organic fibres cannot be sourced from markets, these are speciality products and must be sourced from accredited makers / suppliers.

Design

We design with purpose and longevity in mind at our HQ in Western Australia.

Before we commit to production every piece is reviewed, the measurements are double and triple checked. We measure, fit test and then revaluate quality, colour, fabric wash and trims.

Every detail matters.

quality control

We have our own team on the ground who complete inspections. Even with great makers there can be issues because the part you can’t control is EVERY piece of workmanship, which is why you do occasionally get a faulty piece here and there. It’s important to remember (and not an excuse) that everyone can have an off day at work and this will result in a faulty.

Nobody likes faulty product but they are a part of the production process. We have a less than 1% faulty rate which by industry standards is crazy good and anything we receive at this end that is able to be washed, fixed or repaired - we do it.